11+ Teaching tech calibration cube ideas

Home » tech Info » 11+ Teaching tech calibration cube ideasYour Teaching tech calibration cube images are ready in this website. Teaching tech calibration cube are a topic that is being searched for and liked by netizens now. You can Download the Teaching tech calibration cube files here. Download all royalty-free vectors.

If you’re looking for teaching tech calibration cube pictures information related to the teaching tech calibration cube interest, you have pay a visit to the right site. Our site always provides you with hints for seeking the highest quality video and image content, please kindly hunt and find more informative video content and images that fit your interests.

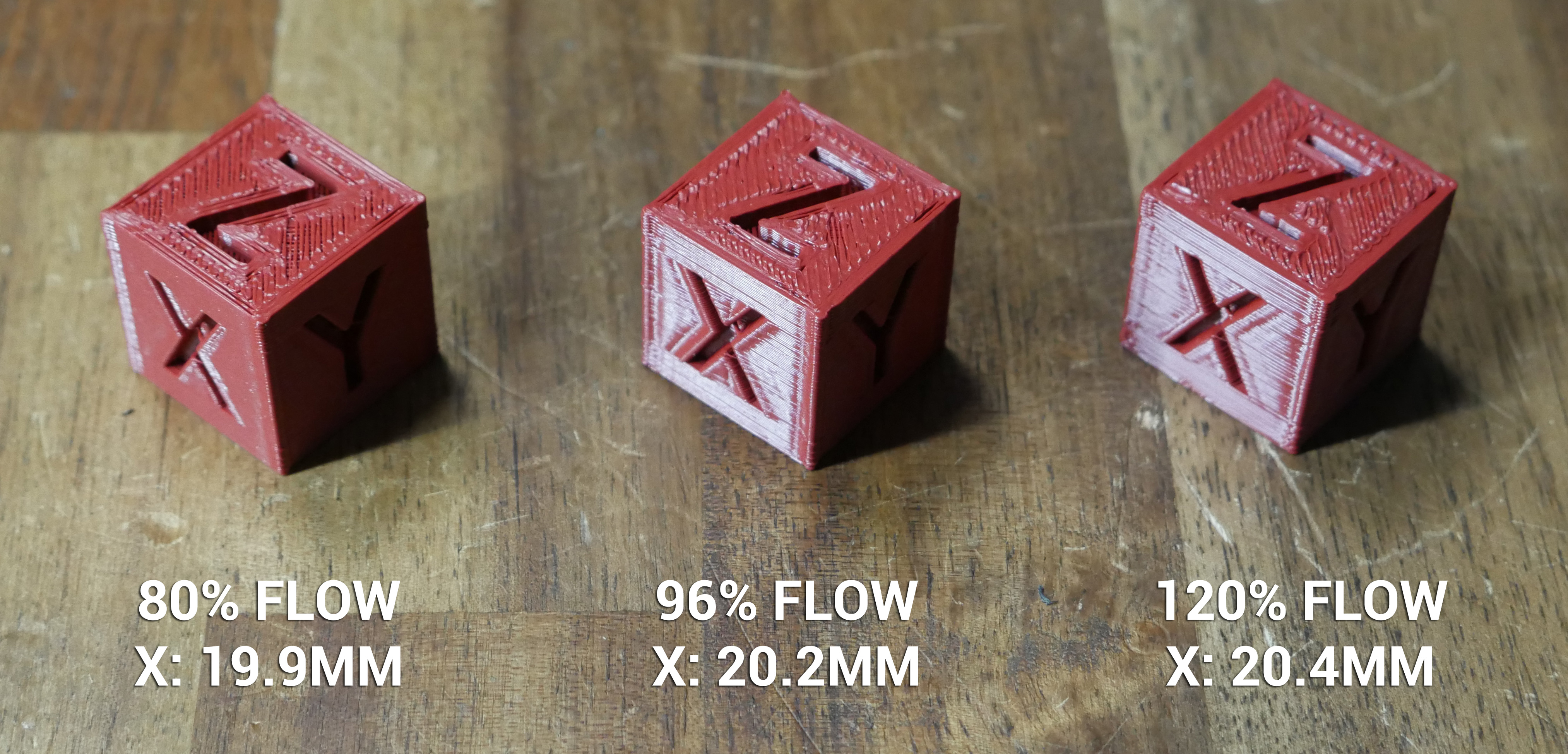

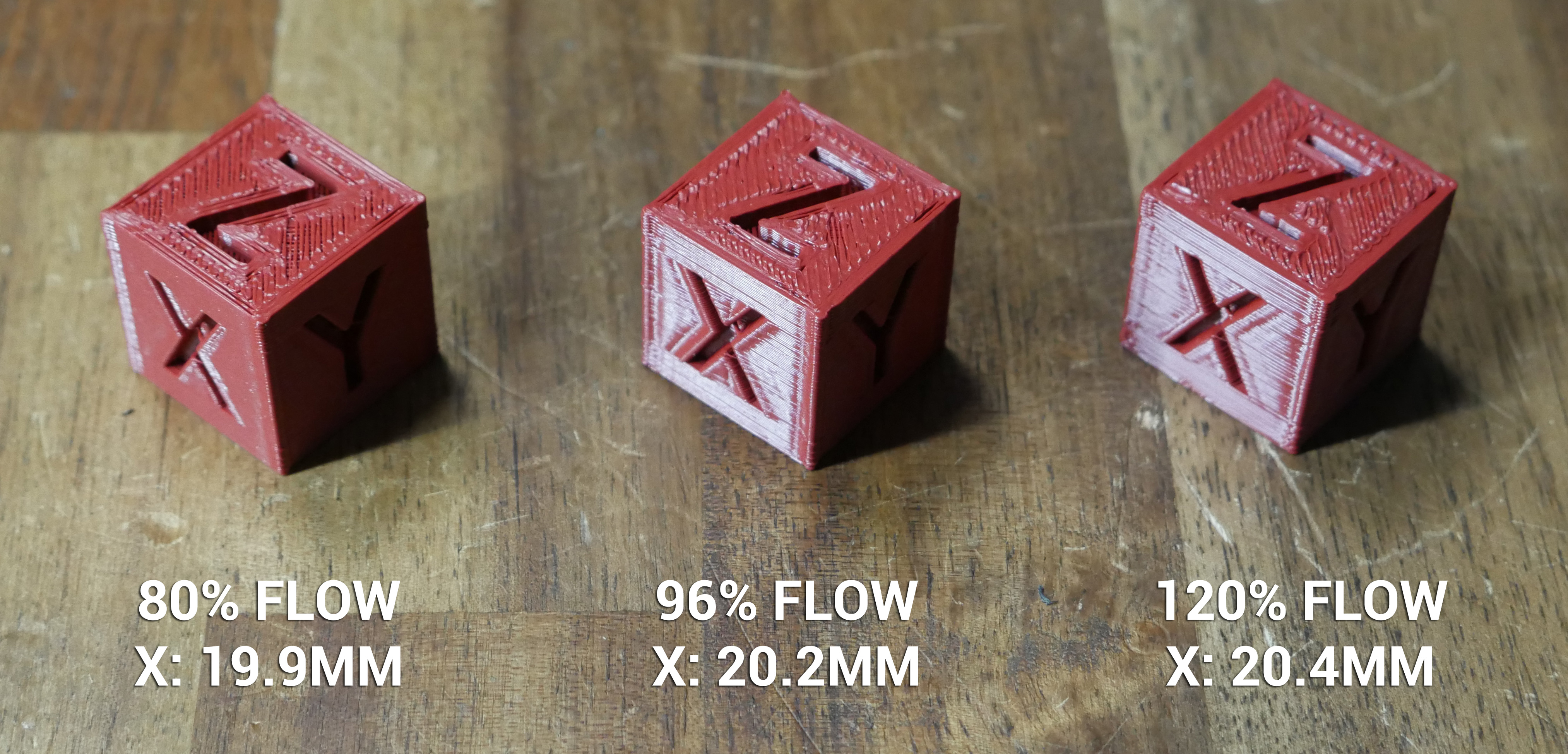

Teaching Tech Calibration Cube. Check out this Ender 3 calibration guide to get the most out of your beloved printer. A simple demonstration of this can be made by printing three 20mm calibration cubes with no changes to the machine but the extruder flow rate altered for each test. Ill reprint a cube when Im done with the overhang test thats running now. If using PETG set a temperature of 225C.

Teaching Tech 3d Printer Calibration From teachingtechyt.github.io

Teaching Tech 3d Printer Calibration From teachingtechyt.github.io

The reason is that sharp corners on the vertical edges and around the bottom of cubes are. This is a plain simple and accurate 20mm cube for use with calibration. If nothing happens download GitHub Desktop and try again. Download files and build them with your 3D printer laser cutter or CNC. For delta set bed size to 0 for x and y. Work fast with our official CLI.

If theres difficulty removing any of the pins theres still something that needs to be calibrated out to achieve tighter tolerances.

I followed the steps laid out here using the Precision Method Cube. Using a micrometer changing the value from 1051 to 1081 had no effect. Thingiverse is a universe of things. If nothing happens download Xcode and try again. The Extrusion multiplier setting has no effect to the extrusion width on my Mini. In the image below the cubes have flow rates of 80 96 and 120.

Source: youtube.com

Source: youtube.com

Work fast with our official CLI. Optimized for 02 mm layer height. Had to change from 212 to 233. It suppose to be smart compact and fulfill several purposes. Corrected the value from 100 to 9302 thickness measurement with the gauge changed from 043mm to 040mm perfect Retraction Tuning.

Source: pinterest.com

Source: pinterest.com

A simple demonstration of this can be made by printing three 20mm calibration cubes with no changes to the machine but the extruder flow rate altered for each test. Then adjust temps fan etc. A well-calibrated 3D printer always gives better results. Your codespace will open once ready. When I got to calibrating my E-steps I found that I was under extruding by about 10 - only put out 90 mm of filament.

Source: teachingtechyt.github.io

Source: teachingtechyt.github.io

Thingiverse is a universe of things. Check out this Ender 3 calibration guide to get the most out of your beloved printer. Download files and build them with your 3D printer laser cutter or CNC. C CA CBA C C. Download files and build them with your 3D printer laser cutter or CNC.

Source: youtube.com

Source: youtube.com

Yet another temperature calibration tower. When I got to calibrating my E-steps I found that I was under extruding by about 10 - only put out 90 mm of filament. If using PETG set a temperature of 225C. Corrected the value from 100 to 9302 thickness measurement with the gauge changed from 043mm to 040mm perfect Retraction Tuning. Then adjust temps fan etc.

Source: teachingtechyt.github.io

Source: teachingtechyt.github.io

For delta set bed size to 0 for x and y. Optimized for 02 mm layer height. If nothing happens download Xcode and try again. Download files and build them with your 3D printer laser cutter or CNC. Your codespace will open once ready.

Source: teachingtechyt.github.io

Source: teachingtechyt.github.io

If theres difficulty removing any of the pins theres still something that needs to be calibrated out to achieve tighter tolerances. For bowden start with 5 starting retraction and 5 incriment. Exported by Simplify3D 412 -. STEP models have been added. A calibration cube is usually a classic cube with concave X Y and Z letter on the surface and can be printed to detect issues like 3D printing ghosting Z wobbling elephant foot and inaccurate X Y or Z axis dimension and tune a 3D printer to the best condition accordingly.

Source: youtube.com

Source: youtube.com

A calibration cube is usually a classic cube with concave X Y and Z letter on the surface and can be printed to detect issues like 3D printing ghosting Z wobbling elephant foot and inaccurate X Y or Z axis dimension and tune a 3D printer to the best condition accordingly. Then adjust temps fan etc. Work fast with our official CLI. In the image below the cubes have flow rates of 80 96 and 120. Tried the values from 05 to 14 of Retraction distance always at 40mm sec of speed but on no case I had traces of stringing.

Source: pinterest.com

Source: pinterest.com

Have a question about this project. First try with defaults. Yet another temperature calibration tower. Check out this Ender 3 calibration guide to get the most out of your beloved printer. Download files and build them with your 3D printer laser cutter or CNC.

Source: thingiverse.com

Source: thingiverse.com

Slicer Flow Calibration different thicknesses on walls of cube Issue 148 teachingtechYTteachingtechYTgithubio GitHub. Thingiverse is a universe of things. The Best 3D Printer Calibration Cubes in 2021. Thingiverse is a universe of things. Tried the values from 05 to 14 of Retraction distance always at 40mm sec of speed but on no case I had traces of stringing.

Source: pinterest.com

Source: pinterest.com

Ender 3 ProV2 Calibration. This is a plain simple and accurate 20mm cube for use with calibration. Have a question about this project. I followed the steps laid out here using the Precision Method Cube. It is functioning as a regular temperature tower it contains several test patterns like overhangs from 60 deg to 25 deg bridges from 15 mm - 30 mm stringing test curvy shapes One floor is exactly 10 mm and stand is 14 mm.

Source: youtube.com

Source: youtube.com

For direct drive start with 5 starting retraction and 25 incriment. Running through the Teaching Tech calibration steps. Download files and build them with your 3D printer laser cutter or CNC. Use Git or checkout with SVN using the web URL. Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

Source: ar.pinterest.com

Source: ar.pinterest.com

When I got to calibrating my E-steps I found that I was under extruding by about 10 - only put out 90 mm of filament. If seeking to sort out linear dimension accuracy on a 3D printer it might be an idea to avoid sharp-cornered calibration cubes such as the one in the photo and go for something with rounded vertical corners instead. Had to change from 212 to 233. Check out this Ender 3 calibration guide to get the most out of your beloved printer. STEP models have been added.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title teaching tech calibration cube by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- 15+ Southeast asia tech unicorns info

- 16++ Big tech podcast ideas in 2021

- 11++ Tech area home info

- 13++ Opentable tech uk blog info

- 15++ Tech huawei blog information

- 13++ What does a technology evangelist do ideas in 2021

- 18++ Big tech net zero ideas

- 16++ Tech corp questions ideas

- 11+ Tech entrepreneur csc ideas in 2021

- 17+ Technical guruji net worth ideas